The combination of supply chain bottlenecks and rising construction continues to have a significant impact on residential and commercial construction firms and contractors.

Building material costs are up 19% from 2018 to 2022, according to the National Association of Home Builders reports. Since the beginning of this year alone, building materials prices have increased 4.9%1

Here's how different areas are impacted:

- Shipping costs: 4x higher than March 20202

- Steel: more than 2x in price since March 20203

- Softwood lumber: almost 2x in price since September 20213

- Exterior and interior paint: Up 30.3% and 21.2% respectively4

- Home appliances: 13% higher costs than last year5

The question facing today’s contractors is how to address these issues with customers. How can you plan for prices changing almost daily and still come out profitable?

There are a number of ways contractors are combating these forces of change. Some are stockpiling materials. Others are using unskilled labor. Some are opting to hold off on projects and wait it out. Others are choosing to forge ahead, hoping they’ll still somehow make a profit in the face of 9.1% inflation.6

To determine the best way to weather the inflation storm, it’s important to make educated decisions from a position of strength. Doing so will lead you to successfully determine how to manage costs, reduce risk, and ultimately, turn a profit.

3 ways contractors are trying to avoid inflation and the risks associated with them

While large contractors may be able to withstand cost increases by relying on their cash reserve, most smaller or newer contractors can not.

Pricing in the current market is a tricky balancing act made more perilous because the choices you make increase your risk.

Here are three common ways contractors are currently combatting rising costs and the risks associated with each of these approaches.

1. Finding cheaper supplies and materials

One way to save costs is to seek out less costly materials.

The challenge is: Clients may not be pleased with the overall aesthetic of poorer quality materials. Or, worse, materials may not hold up.

That cheap bathroom trim turns out to be susceptible to water damage and wilts under humidity. You may face an errors and omissions claim — or have to redo the project later without adequate compensation.

Using cheaper materials might even lead to negative health consequences that could have repercussions for your business.

For example, Chinese-made drywall has been linked to issues such as breathing difficulties, asthma and skin irritations.7 Years ago, homeowners in a number of states successfully sued developers, suppliers and manufacturers over issues caused by Chinese-made drywall.8

2. Hiring less-skilled labor

Every contractor has felt the effects of the current labor shortage as skilled workers age out of the workforce with no back bench to step in. The construction industry faces a worker shortage of 650,000 people this year.9

Less skilled workers may lower your labor costs initially, but those individuals can make more mistakes and need more oversight.

They could also be a danger to themselves or others — which could lead to a lawsuit or a workers’ compensation claim. These issues can spiral into time delays, which will ultimately cost you more money.

3. Stockpiling materials and supplies

Buying up materials at lower prices and holding onto them seems like a worthwhile strategy but doing so carries costs and risks.

You may have to rent or build storage space to house extra materials.

And leaving materials on a job site could result in weather-damaged goods or theft, which has risen along with the cost of materials. According to the National Equipment Register, up to $1 billion in construction equipment, appliances and materials are stolen each year.10

Safeguarding your business by reducing your risk: 6 ways to truly protect your bottom line

While securing cheaper supplies and materials, hiring less skilled labor and stockpiling materials and supplies may be tempting, there are other ways to protect your bottom line and reduce risk simultaneously.

1. Use your contract to transfer risk

Including particular clauses in your contract can help you transfer the risk of increased costs to the building owner or homeowners.

One of the most common is an “escalation clause,” which allows a contractor to adjust the contract via change order when price increases are out of your control.

You can include language defining the increase, for example, “if material prices rise by x%, here is what will happen.”

The NAHB has a sample escalation clause11 that may be helpful to include in your contracts.

Your contract also might include a “force majeure” clause, which can include language-related cost increases that occur because of “acts of God” such as floods or earthquakes, or human-caused events such as terrorist acts. Because these events are considered out of one’s control, pandemic-related costs might be included in this contract language, as well.12

Other clauses to consider include those for material delays, material substitution or even a termination clause if prices get so out of control.

This information is for educational purposes only. It’s important to consult with a legal professional before you make any contractual changes.

2. Consider new vendors and partnerships

You may have worked with the same suppliers for years, but now might be the time to widen your scope and network. Search for new suppliers and manufacturers online, join professional organizations, and connect with your local chamber of commerce.

How can a new supplier help you improve profitability?

They might have access to more and/or newer products. A new supplier might have different rebate deals or more favorable contract terms.

Once you find options, do your due diligence to make sure companies are reliable.

You might also band together with other small- and medium-sized contractors through a buying group. There is power in numbers, so you’ll be able to reap the benefits of economies of scale.

3. Increase profitability of each project

With so many elements outside of your control, it’s difficult to see that despite rising costs, you still might be able to earn more on projects.

You’ve probably heard the phrase, “work smarter, not harder.”

That means focusing on productivity and efficiency and staying on top of your actual costs. For this, upfront planning for every project is crucial. Here are four steps to do just that:

- Understand your true costs by breaking down a project into phases such as framing, drywalling and electric installation. Break that down further by defining the tasks needed to complete the phase. Now, look at those tasks through the lens of labor, materials and overhead.

- Accurately estimate your profit. You may love building, but all business owners are in business to make a profit. Don’t shortchange yourself.

Once you know your costs, you need to calculate markup13 (total sales divided by job costs) in order to profit over and above what it costs you to do a job.

Michael Stone, owner of Construction Programs & Results and author of Markup & Profit, A Contractor’s Guide For New Home Construction, suggests marking up new home construction projects at minimum 1.26 (max 1.45). That means taking 100% of your costs and adding 26% of your costs; or, in other words, multiply your price by 1.26.

- Manage/track costs. Doing this accurately will help you stay within your budget. You want to keep track of direct and indirect expenses. There are plenty of software tools that can help you accurately track your costs in real time and then create reports.

- Analyze results. Don’t wait until the project retrospective to see if you got it right. Periodically check the accuracy of your estimates and costs and that your project is following the path toward on-time completion. Keep open clear lines of communication with all stakeholders to help you in your analysis.

4. Keep clients informed

Clients are aware of what’s happening in the world. They know about shortages and supply chain delays and want projects completed as quickly as you do.

Be open with them about the schedule or material delays as you become aware of them. This will build trust, and since clients are the ones to authorize change orders, they will appreciate value engineering options to help their project stay on budget and finish as close to on time as possible.

This protects your bottom line, as well. No client wants to see a contractor go belly up, leaving everyone in the lurch.

5. Get the right information from the client before you start

To avoid change orders, manage client expectations upfront.

Let them know about current costs and the likelihood of price increases. Under promise and overdeliver. And when it comes to bidding situations, do yourself a favor and prepare accurate, detailed scopes of work to minimize surprises.

6. Evaluate projects after they are completed

This is one of the most important best practices a contractor can perform. Information on its own is useless unless you put it to use.

Analyze results by doing a post-mortem on each job. When a project is 100% done (all the way through punch list), gather together everyone who worked on the project and do the following:

- Compare estimates vs. actual costs

- Discuss where things might have gone wrong

- Pinpoint areas of slippage

- Define what went well or could have been done better

- Determine what procedures and systems might need to be changed

Then use your assessment to reduce the likelihood of repeating those mistakes and find cost-saving measures for future projects. Keep in mind that the more accurate you are with your costs and estimates, the easier time you’ll have with your post-project analysis.

Today and beyond

According to industry economists, supply chain disruptions will eventually even out — but not anytime in the near future.14 Inflation, too, will be around for the near term. The labor shortage will also continue long into the future.

But don’t be discouraged. As you move forward, factor possible future costs into your estimates, amend contract language, network with other industry professionals and communicate with your clients.

When it comes to business, the only constant is change. Preparation is key: Analyze your progress and catalog what you’ve learned so you can work smarter and lessen your risk.

How NEXT helps construction businesses

NEXT is one of the leading insurance providers for small construction companies.

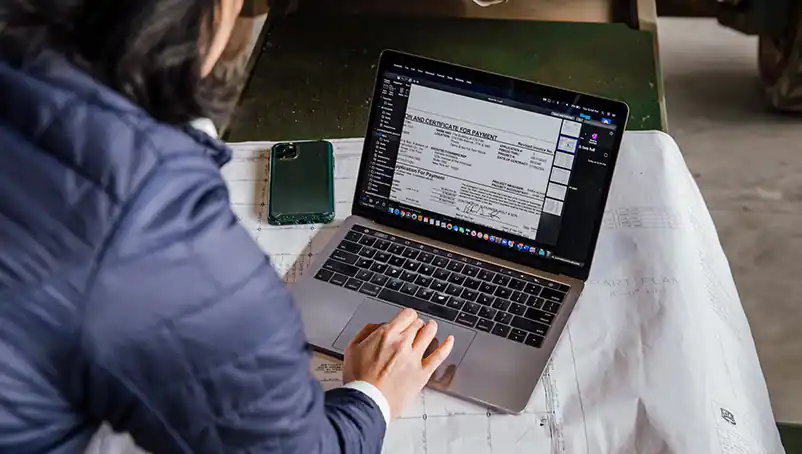

We make it easy to quickly get a quote, buy coverage and get instant access to your certificate of insurance.

When you’re a NEXT customer, you can easily share your COIs from anywhere, 24/7, with our easy mobile app or website.

Start a free quote today or visit our website to learn more about construction business insurance.

Sources